As a modern material supply solution, the central feeding system not only offers advantages in terms of increased efficiency and accuracy, but also makes a positive contribution to the environment and sustainable development. The following will be introduced Central feeding system Plays an important role in environmental protection and sustainable development.

First, a central feeding system reduces material waste. Traditional feeding methods often lead to waste and loss of materials. Manual handling and distribution of materials are prone to errors and oversupply, which can be avoided by centralized control and precise delivery of the central feeding system. From the storage area to the use of the process, the material can achieve accurate delivery, reduce waste and loss, reduce the impact of resource consumption on the environment.

Second, a central feeding system can reduce energy consumption. The system reduces manpower and energy consumption through automated conveying equipment and precise control. Compared to traditional manual handling methods, the central feeding system can use energy more efficiently, reduce unnecessary energy waste, and reduce the negative impact on the environment. Over a long-term time horizon, this will help drive sustainable development and energy conservation and emission reduction goals.

In addition, a central feeding system can improve workplace safety. Traditional feeding methods may be at risk of human error and accidents, while the automation and intelligence of the central feeding system can reduce the involvement of personnel in the material supply process, reduce the possibility of accidents, and improve workplace safety and employee health.

In summary, the central feeding system not only has advantages in terms of increased efficiency and accuracy, but also makes a positive contribution to the environment and sustainable development. The system contributes to sustainable development goals by reducing material waste, reducing energy consumption and improving workplace safety. With the center Feed system We have reason to believe that it will play an increasingly important role in promoting environmental protection and sustainable development.

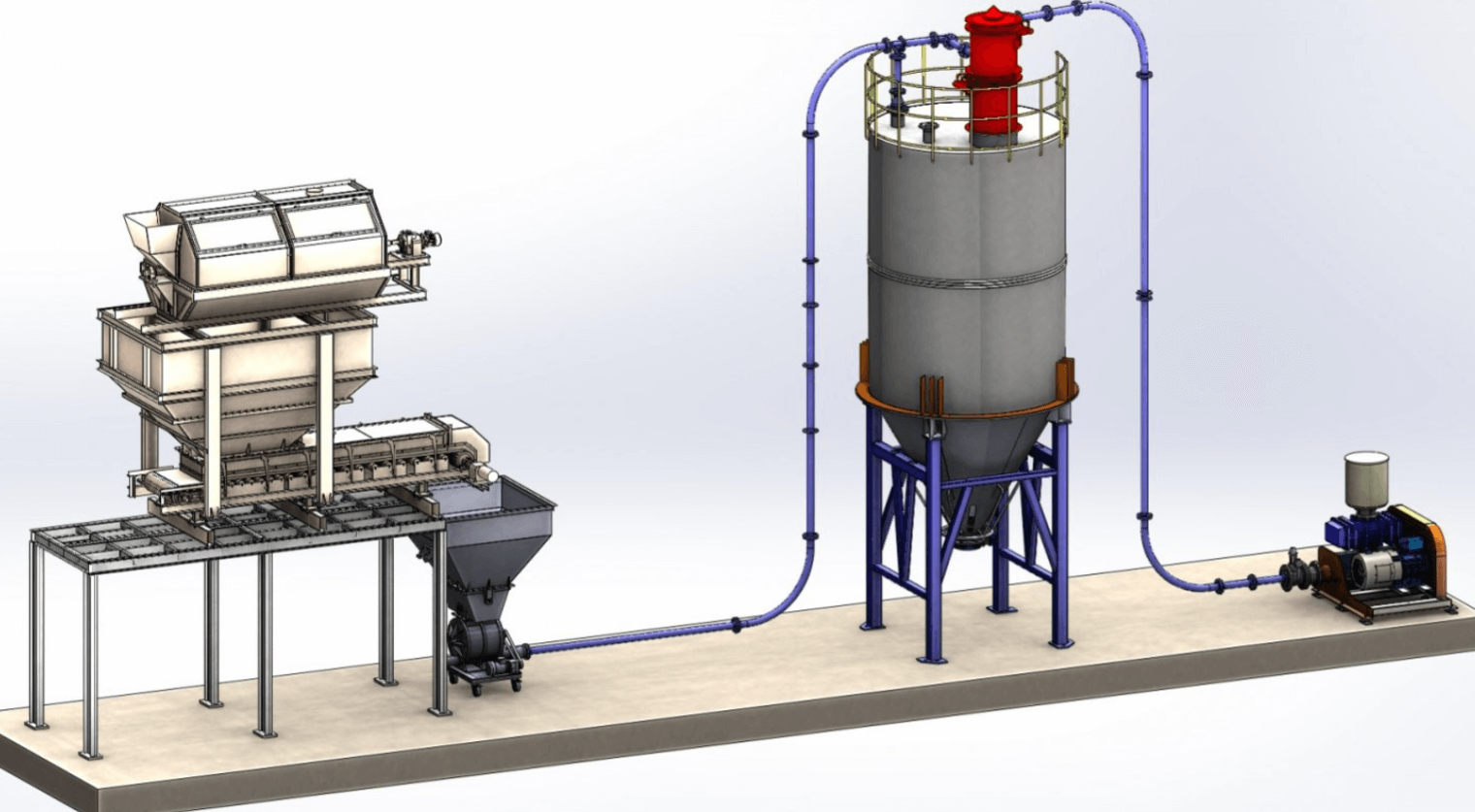

In the grain processing industry, pneumatic conveying system is an important material conveying method, which is widely used in the process of grain storage, cleaning, drying, grinding and so on. Compared with traditional mechanical conveying methods, pneumatic conveying systems have the following advantages

Pneumatic conveying system plays a key role in cement production, which is mainly used in raw material conveying, pulverized coal conveying, clinker conveying and other links in cement production line. The following is the application of pneumatic conveying system in cement production

The Central feeding system is a modern feeding solution that provides efficient and accurate material supply for a variety of industrial and commercial sectors. The system is composed of centralized control unit, conveying equipment and distribution mechanism, which can realize automatic and intelligent material supply management. The advantages and applications of the central feeding system are described below.

As a modern material supply solution, the central feeding system not only offers advantages in terms of increased efficiency and accuracy, but also makes a positive contribution to the environment and sustainable development. The important role of central feeding systems in environmental protection and sustainable development is described below.

Founded in 1926, Garton is one of the largest and most advanced food enterprises in Hong Kong at that time. Garton's main production facilities are located in Hong Kong and mainland China, producing food products including bread, biscuits, cakes, confectionery, etc. Since the 1980s, Garton has been actively developing the Chinese market.