Wijay's scientific research and innovation work has once again made new breakthroughs——Obtained 1 invention patent and 4 utility model patents. Up to now, a total of more than 50 invention patents, enterprise innovation level in the industry continues to maintain a leading edge.

Invention patents:

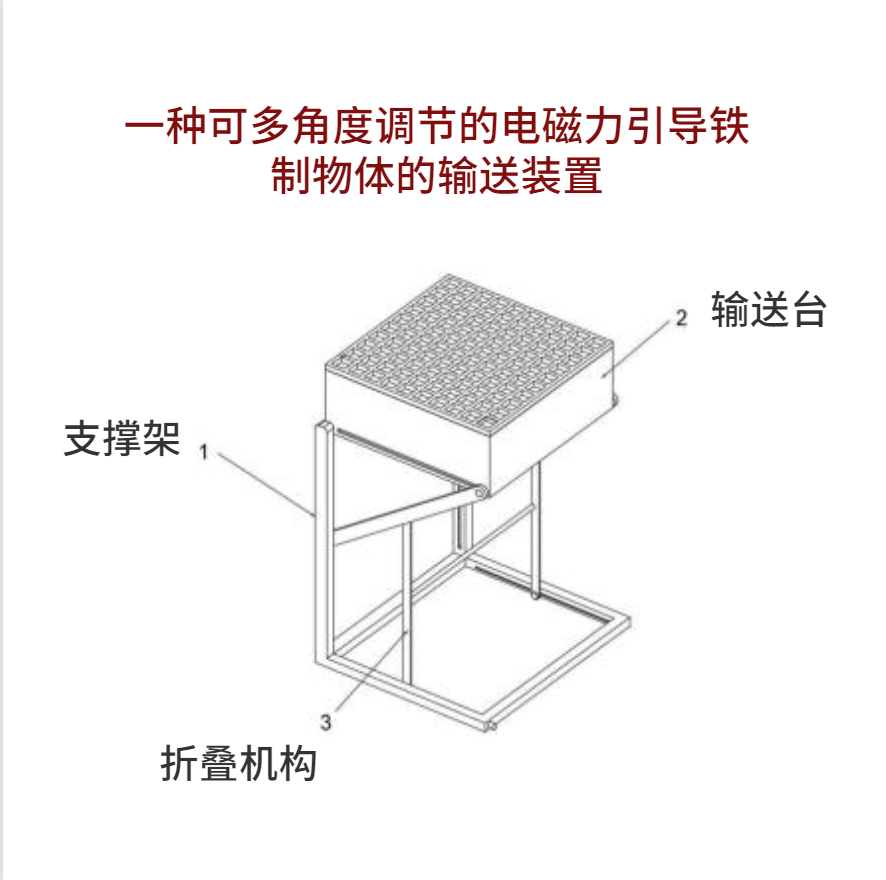

The utility model relates to a conveying device for an iron object guided by an electromagnetic force that can be adjusted at multiple angles

Utility model patent:

The utility model relates to a discharge valve for conveying powdery materials

The utility model relates to a powder dense phase conveying system

The utility model relates to an on-line water inlet control device for a hydraulic conveying system

The utility model relates to a dust collector for a material conveying system

Abstract of invention patent:

The invention relates to the technical field of conveying iron objects, in particular to a conveying device for guiding iron objects with an electromagnetic force that can be adjusted at multiple angles. The folding mechanism comprises at least a first folding arm and a second folding arm, the side wall surface of one end of the first folding arm is provided with a first connecting hole, the side wall surface of the other end of the first folding arm is provided with a second connecting hole, the center of the lower surface of the first folding arm is provided with an hinged slot, a fixed column is fixed in the hinged slot, and an hinged rod is hinged on the fixed column. One end of the articulated rod is provided with a first articulated hole, the first folding arm and the second folding arm are symmetrically arranged, through the folding mechanism set, through the folding connecting rod structure composed of the first folding arm and the articulated rod, the conveyor table can be flipped, and then the plane, inclined plane and vertical plane conveying state can be switched at will, at the same time, the folding mechanism provides support for the conveyor table. To ensure the stability of the conveyor table.

In the grain processing industry, pneumatic conveying system is an important material conveying method, which is widely used in the process of grain storage, cleaning, drying, grinding and so on. Compared with traditional mechanical conveying methods, pneumatic conveying systems have the following advantages

Pneumatic conveying system plays a key role in cement production, which is mainly used in raw material conveying, pulverized coal conveying, clinker conveying and other links in cement production line. The following is the application of pneumatic conveying system in cement production

The Central feeding system is a modern feeding solution that provides efficient and accurate material supply for a variety of industrial and commercial sectors. The system is composed of centralized control unit, conveying equipment and distribution mechanism, which can realize automatic and intelligent material supply management. The advantages and applications of the central feeding system are described below.

As a modern material supply solution, the central feeding system not only offers advantages in terms of increased efficiency and accuracy, but also makes a positive contribution to the environment and sustainable development. The important role of central feeding systems in environmental protection and sustainable development is described below.

Founded in 1926, Garton is one of the largest and most advanced food enterprises in Hong Kong at that time. Garton's main production facilities are located in Hong Kong and mainland China, producing food products including bread, biscuits, cakes, confectionery, etc. Since the 1980s, Garton has been actively developing the Chinese market.