01

System composition

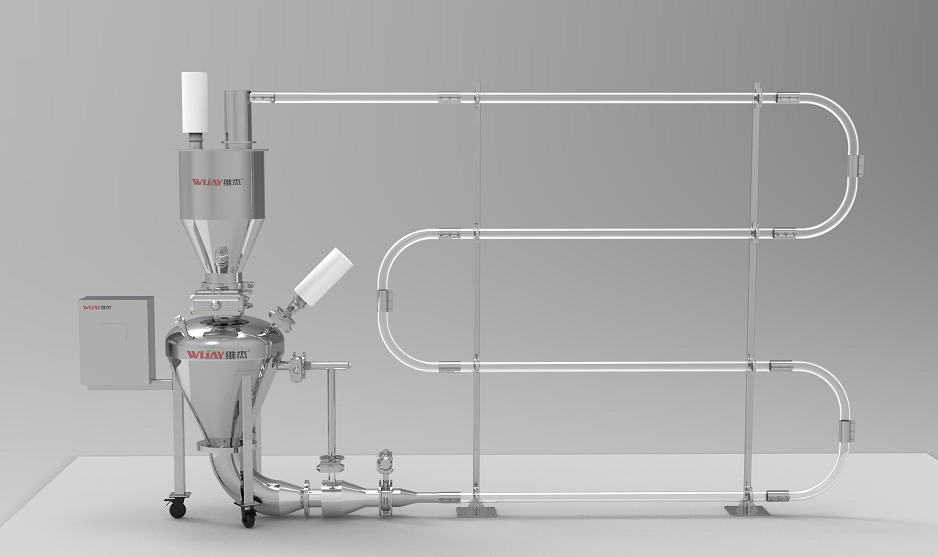

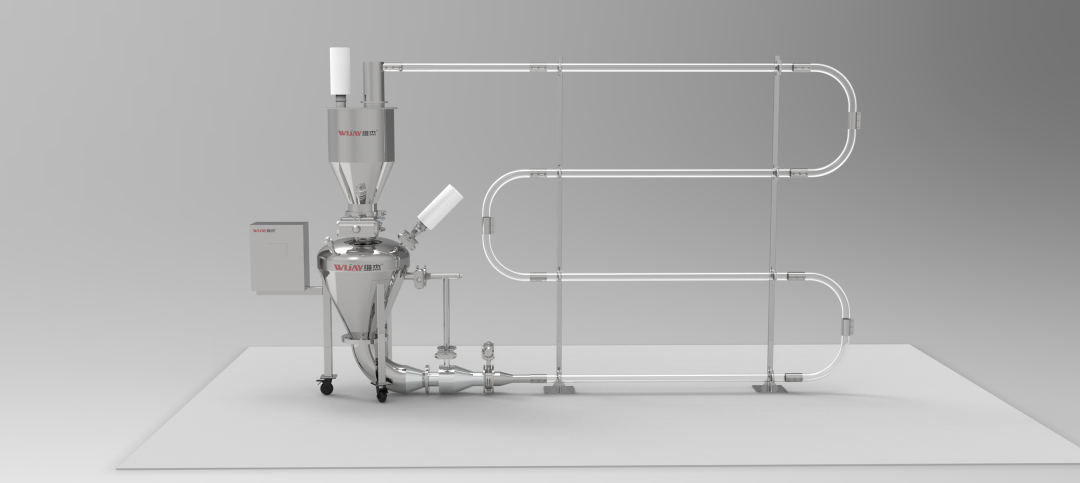

Dense phase transport system

The positive compaction box conveying system developed by Wijay is composed of material temporary storage module, electronic control module and bin pump system.

02

System composition decomposition

Material storage module: The material is transferred to the storage bin through the feeding port, and the air in the bin is discharged through the exhaust port

Electronic control module: The system adopts PLC control, which can set the conveying amount and conveying speed of materials through simple and intelligent operation interface, easy and flexible operation, reduce labor cost and transport efficiency is more efficient.

Bin pump system: The material falls into the pump through the feed valve, and when it reaches the high level of the tank body, the feed valve is closed. Under the action of the air compressor, the compressed air enters the bin pump through the intake valve, and the material is pushed downward under the action of the compressed air. Under the action of the pulse valve, the material is exported to the rear bin through the discharge valve in the form of a column embolism. When the material in the bin pump is completed, the discharge valve and pulse air break valve are closed, and the remaining air in the bin is discharged through the exhaust valve under the action of the compressed air output from the air machine.

The positive compaction box conveying system of Wijay is suitable for long-distance powder and granular material conveying, which can effectively avoid the problems of fragile materials and mixture decomposition in the transportation process, and the material is transported in the closed pipeline to avoid the interference of the external environment on the material, but also reduce the dust exposure, and ensure the cleanliness of the production environment, which is very important for the chemical industry, lithium battery and food industry.

In the grain processing industry, pneumatic conveying system is an important material conveying method, which is widely used in the process of grain storage, cleaning, drying, grinding and so on. Compared with traditional mechanical conveying methods, pneumatic conveying systems have the following advantages

Pneumatic conveying system plays a key role in cement production, which is mainly used in raw material conveying, pulverized coal conveying, clinker conveying and other links in cement production line. The following is the application of pneumatic conveying system in cement production

The Central feeding system is a modern feeding solution that provides efficient and accurate material supply for a variety of industrial and commercial sectors. The system is composed of centralized control unit, conveying equipment and distribution mechanism, which can realize automatic and intelligent material supply management. The advantages and applications of the central feeding system are described below.

As a modern material supply solution, the central feeding system not only offers advantages in terms of increased efficiency and accuracy, but also makes a positive contribution to the environment and sustainable development. The important role of central feeding systems in environmental protection and sustainable development is described below.

Founded in 1926, Garton is one of the largest and most advanced food enterprises in Hong Kong at that time. Garton's main production facilities are located in Hong Kong and mainland China, producing food products including bread, biscuits, cakes, confectionery, etc. Since the 1980s, Garton has been actively developing the Chinese market.