Chemical raw materials

Powder coating

Liquid raw materials

Pasty material

Powdery material

Auxiliary materials and additives

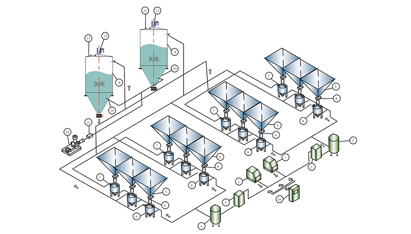

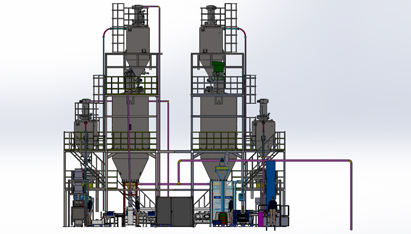

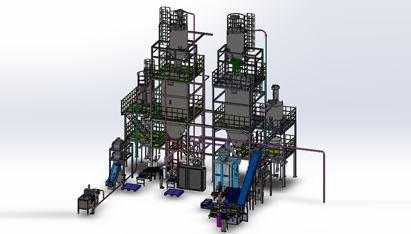

Pneumatic conveying system · Negative pressure pneumatic conveying · Dilute phase pneumatic conveying · Powder pneumatic conveying · Fluid conveying system · Dense phase pneumatic conveying system · Airflow conveying system

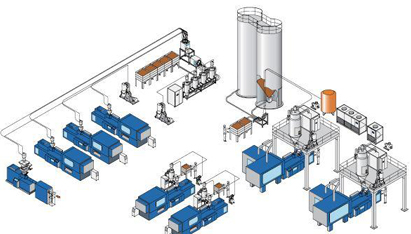

Automatic batching systemAutomatic batching system · Liquid material automatic batching system · Central feeding system · Automatic feeding system

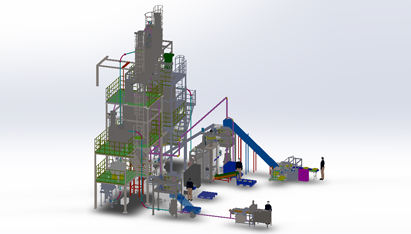

Chemical Industry Production LineChemical battery production line · Fully automated production line for daily chemical products

Chemical Industry Production LineChemical battery production line · Fully automated production line for daily chemical products