01

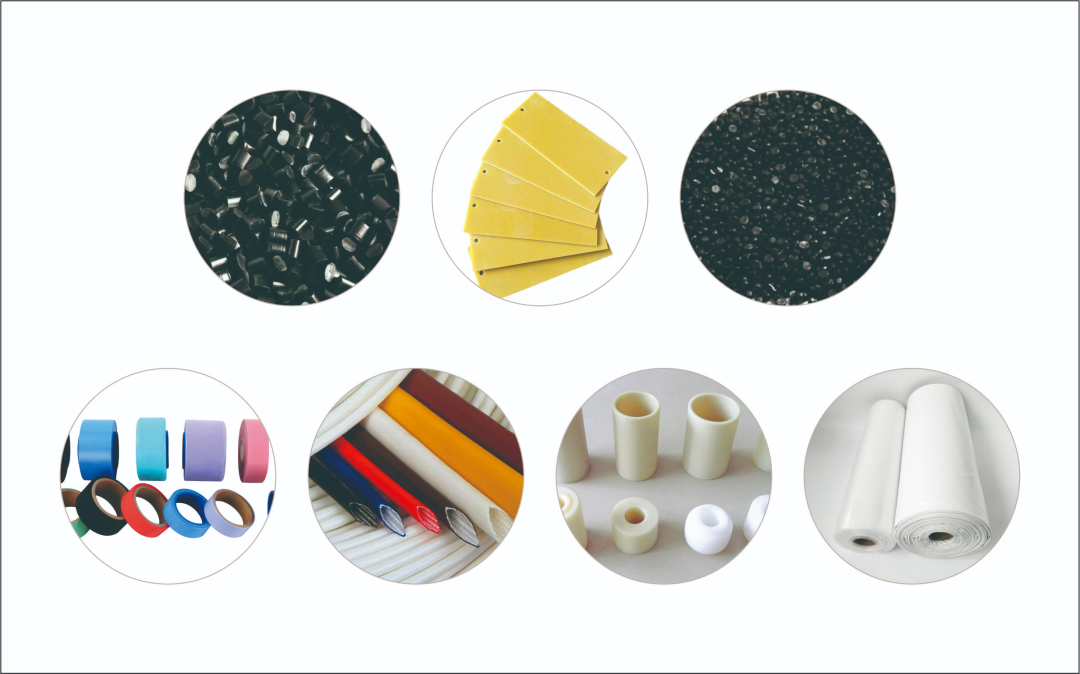

Seven common insulating materials: insulating sheet, insulating pipe, plastic film, rubber, insulating rope, insulating oil, plastic.

1, insulating board: including hard board and soft board. Its types are laminated products, such as 3240 epoxy phenolic glass cloth board and polyvinyl chloride board in engineering plastics, polyethylene board and so on.

2, insulation pipe: including hard pipe and hose. Types of laminated products, such as 3640 epoxy phenolic glass cloth tube, tape or silk roll products.

3, plastic film: such as polypropylene, polyethylene, polyvinyl chloride, polyester and other plastic film.

4, rubber: natural rubber, artificial rubber, silicone rubber, etc.

5, insulated rope: natural silk, artificial fiber woven, such as nylon rope, nylon rope and silk rope (two kinds of silk rope and cooked silk rope), including twisted, woven round rope and ribbon braided rope.

6, insulating oil, insulating paint, insulating adhesive, etc.

7. Plastic. Because the insulation performance of the insulation material at different temperatures will vary greatly, the International Electrotechnical Commission divides the insulation material into seven heat resistance grades Y, A, Z, B, F, H and C according to the maximum operating temperature allowed by the normal operation of the electrical equipment (that is, heat resistance grade). Its allowable operating temperatures are 90℃, 105℃, 120℃, 130℃, 155℃, 180℃ and above 180℃. Y, E, F and H in the above insulation grade symbols can also be represented by DAB, BC and CB, respectively.

02

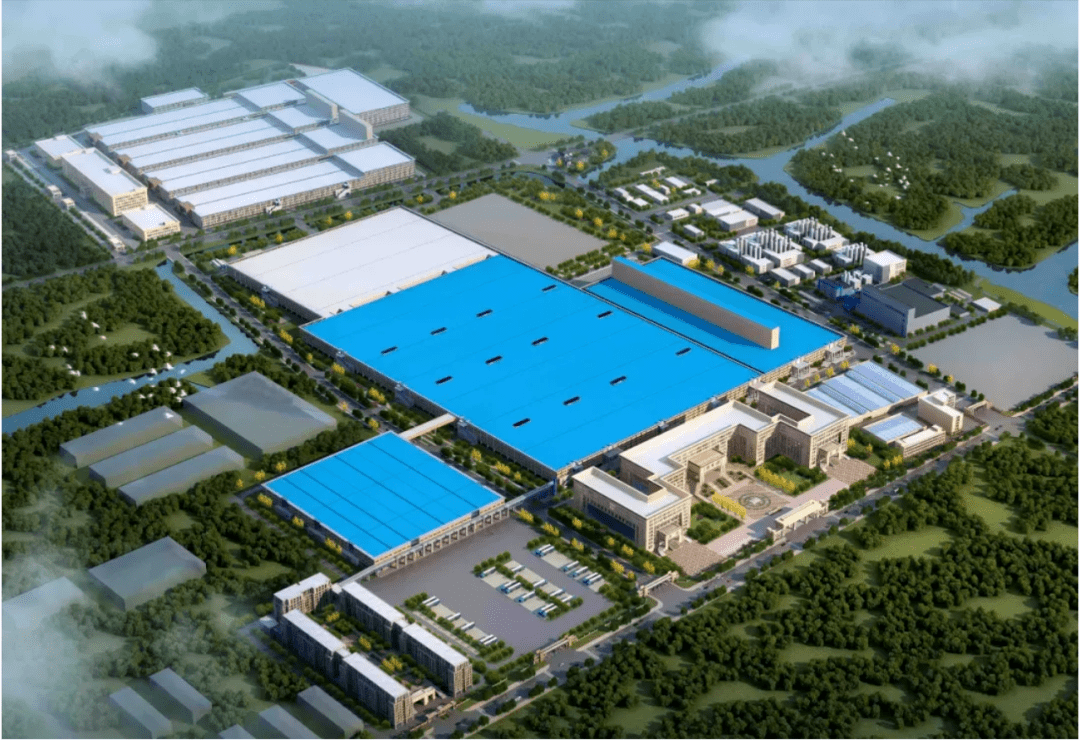

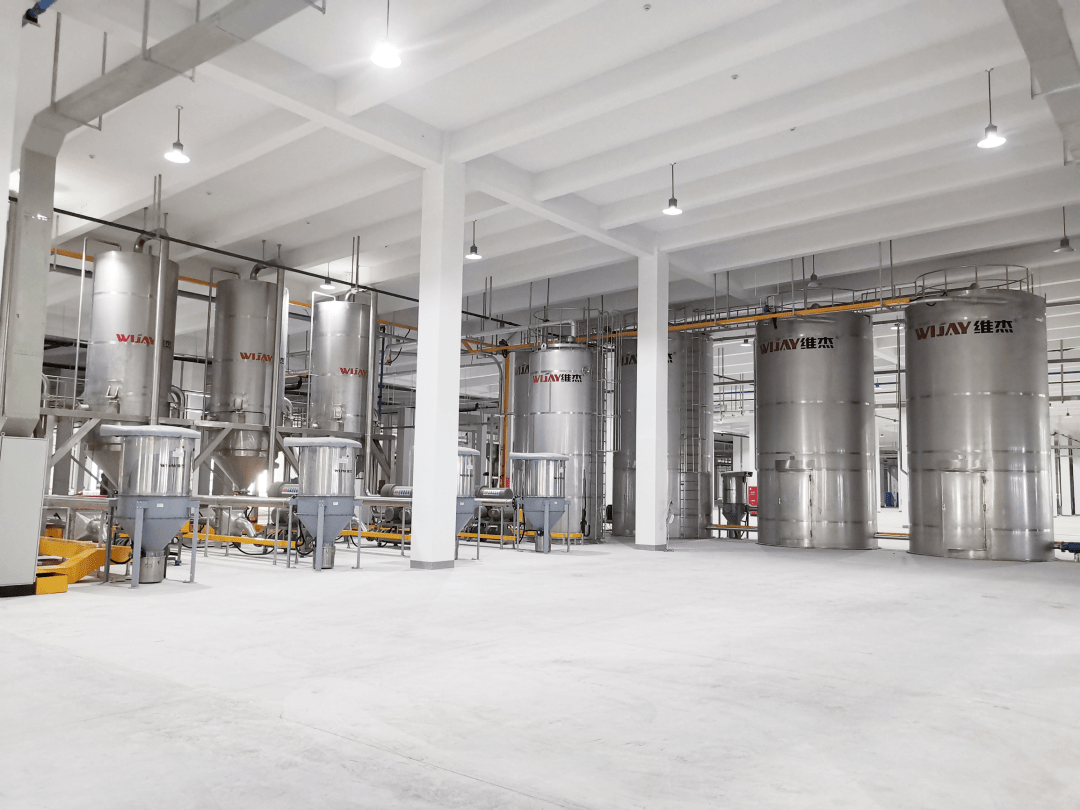

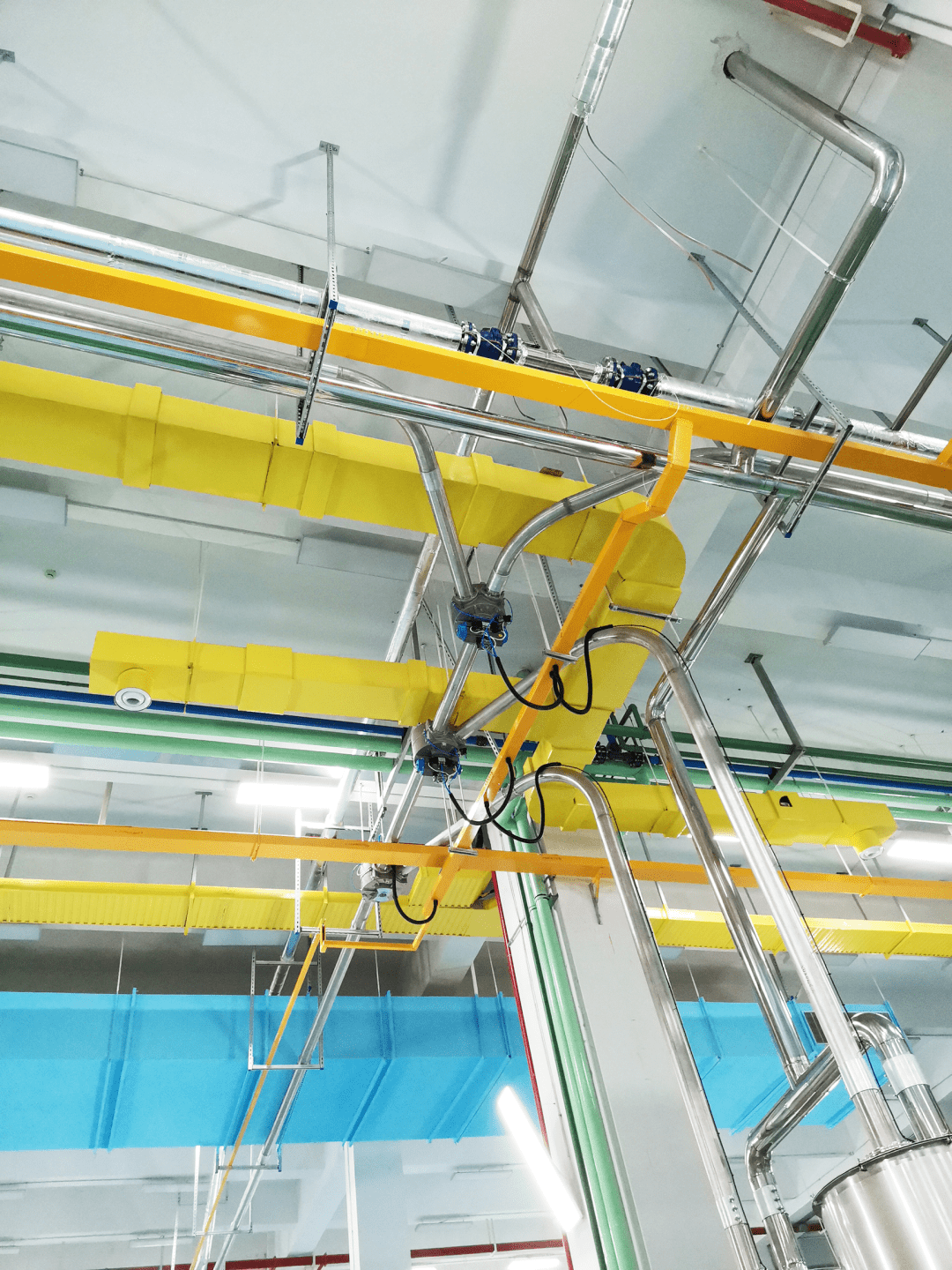

Fortis Group is a leader in the optical communication industry and one of China's top 500 enterprises. Wijay has designed an information and intelligent material automation system for its largest cable manufacturing base in Jiashan.

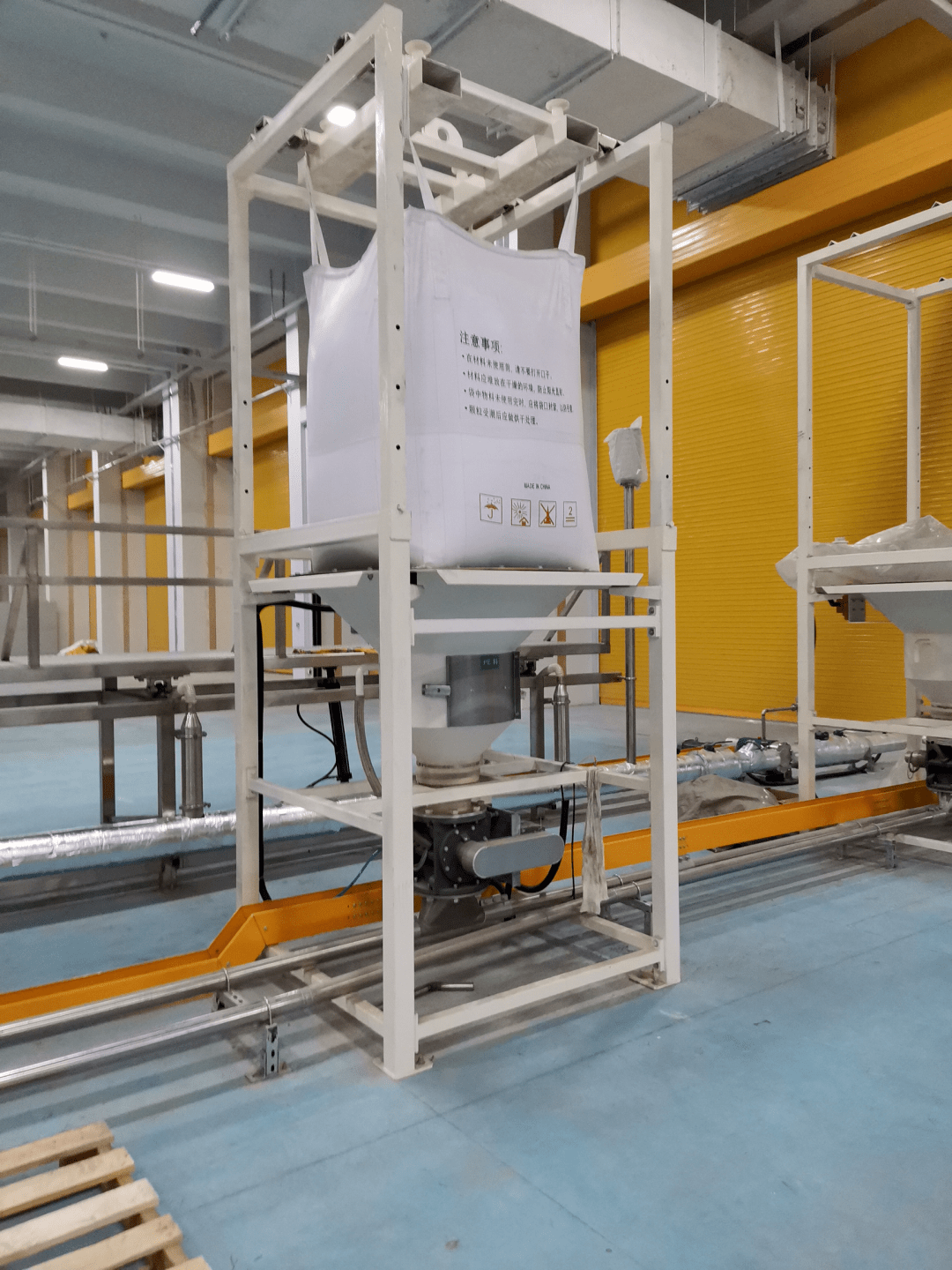

The system can handle 9 kinds of powder raw materials and 2 kinds of paste materials, and the materials can be supplied to 180 production lines in the production base. The system realizes the fully automated centralized feeding, storage, drying, metering and conveying of cable materials with an annual capacity of 90 million core kilometers. The processing capacity is up to 60 tons per hour, and the maximum transport distance is over 600 meters.

03

The project is a comprehensive practice of automation and informatization. All material information and usage have been measured and recorded. The upper computer software of the system is deeply integrated with the MES system of the factory, and is interconnected with the enterprise ERP system, providing a reliable implementation platform for exploring Industry 4.0. The project has successfully solved the technical problems of wire drawing, dust, efficient drying, online metal removal, ultra-long distance conveying and other industries through Wijay's patented technology and innovative technical solutions, which has saved a lot of equipment for customersReserve investment and significantly reduce operating expenses. The on-line grain water content measurement and control technology has greatly improved the product excellence rate and set a new technical benchmark for the industry.

In the grain processing industry, pneumatic conveying system is an important material conveying method, which is widely used in the process of grain storage, cleaning, drying, grinding and so on. Compared with traditional mechanical conveying methods, pneumatic conveying systems have the following advantages

Pneumatic conveying system plays a key role in cement production, which is mainly used in raw material conveying, pulverized coal conveying, clinker conveying and other links in cement production line. The following is the application of pneumatic conveying system in cement production

The Central feeding system is a modern feeding solution that provides efficient and accurate material supply for a variety of industrial and commercial sectors. The system is composed of centralized control unit, conveying equipment and distribution mechanism, which can realize automatic and intelligent material supply management. The advantages and applications of the central feeding system are described below.

As a modern material supply solution, the central feeding system not only offers advantages in terms of increased efficiency and accuracy, but also makes a positive contribution to the environment and sustainable development. The important role of central feeding systems in environmental protection and sustainable development is described below.

Founded in 1926, Garton is one of the largest and most advanced food enterprises in Hong Kong at that time. Garton's main production facilities are located in Hong Kong and mainland China, producing food products including bread, biscuits, cakes, confectionery, etc. Since the 1980s, Garton has been actively developing the Chinese market.