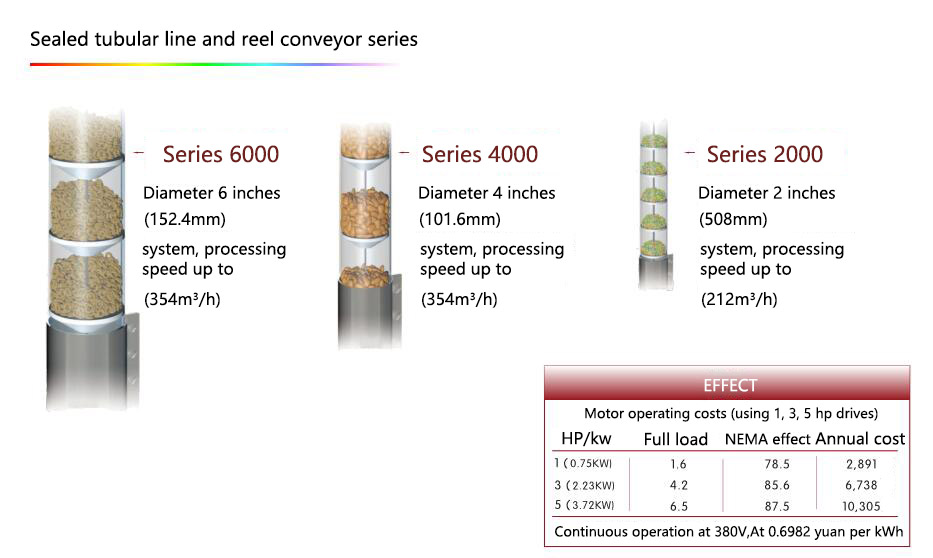

Before using our custom sealed tube line and tray conveyors, we used barrel, pneumatic, belt drive and vacuum review systems, all of which were inefficient. After comparing different options, we chose the sealed tube feed line and tray conveyor based on price, installation, loop time and flexibility.

The breakage rate of beans is reduced78%!

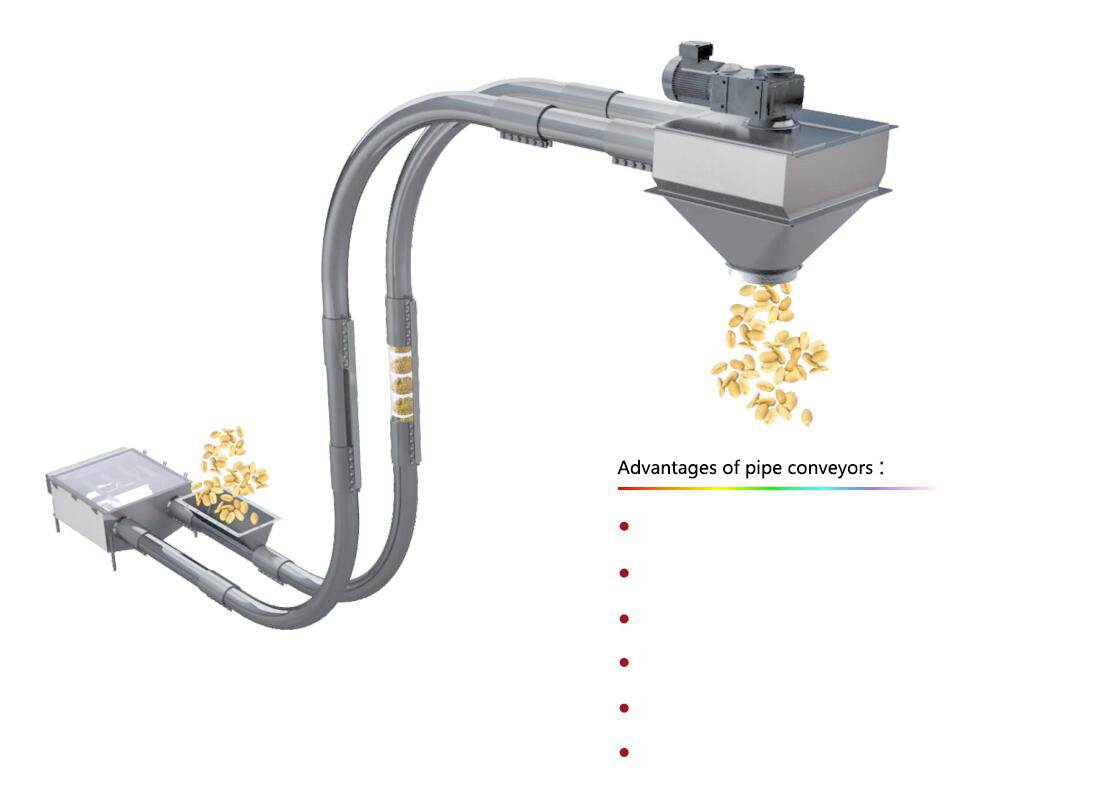

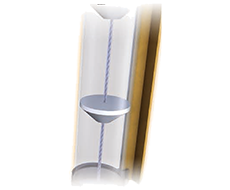

The tray attached to the curved material line gently transports the material in the tube without the use of air.

Cereal bars

cereals

oat

Ring grain

Sunflower seed

Cashew nut

walnut

Frozen strawberry

Green coffee bean

cornmeal

Almond slice

Green tea

Frozen blueberries

Frozen peas

All kinds of crispy food

Soya beans

Ground coffee

hazelnut

popcorn

Dried fruit mix

Soya beans

Frozen corn

almond

Pet food

Roasted coffee

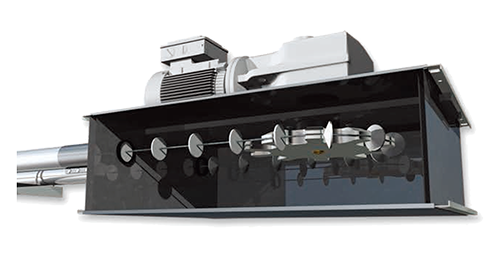

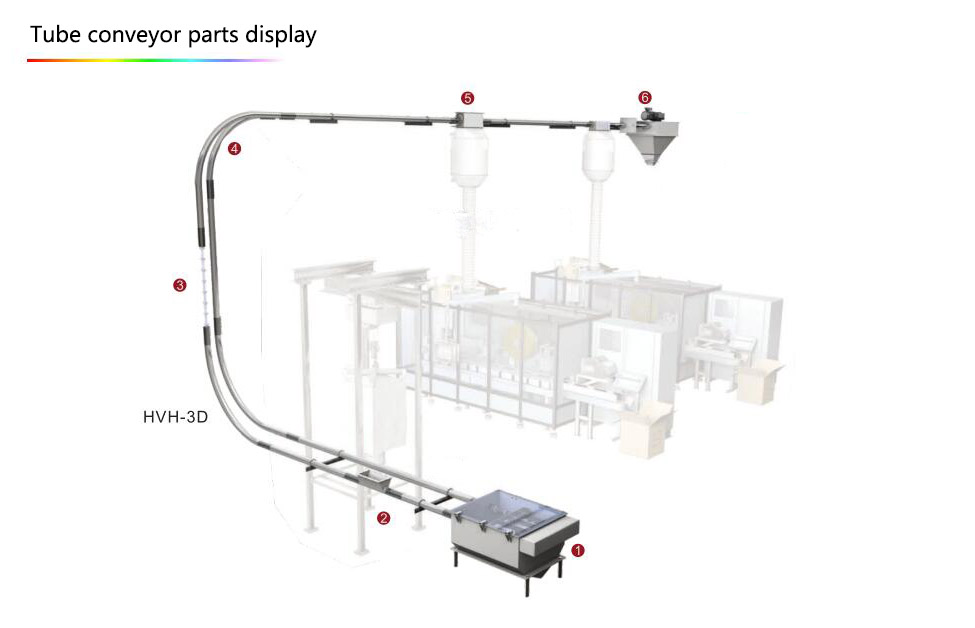

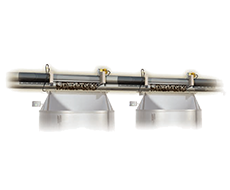

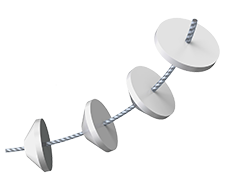

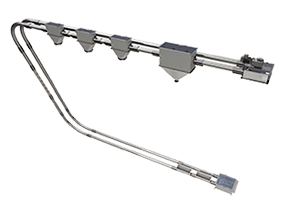

1. Tension rotary device

Automatic adjustment

2. Feed port

Available in a variety of shapes to suit your needs

3. Check the material tube

Transparent and intuitive

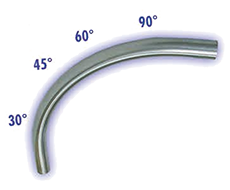

4. Change direction

Amplitude of change

5. Rotate discharge

Multiple outlet options (on demand)

6. Drive device

Compact and low horsepower

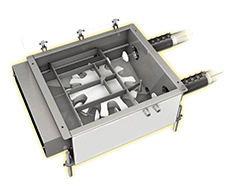

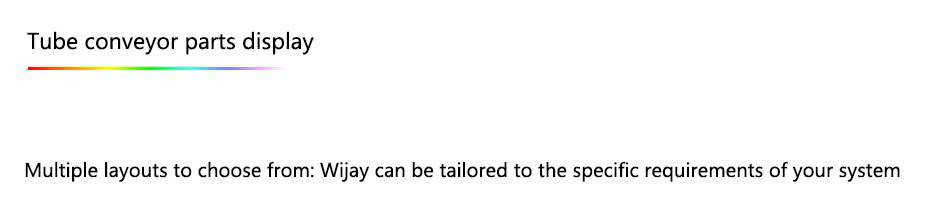

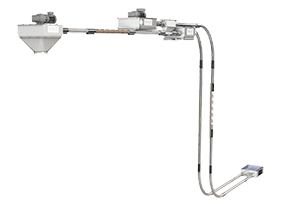

Straight line brush box

Automatic cleaning/material line

System core material line and tray

This method can be very flexible in conveying various raw materials

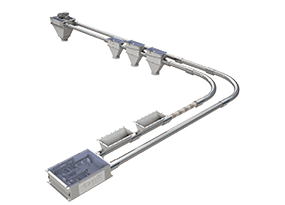

Linear form

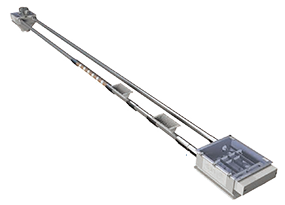

HVH

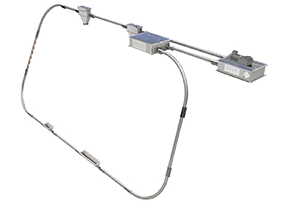

ring-type

U-shaped horseshoe

Horizontal corner

conveyor