pulverizer

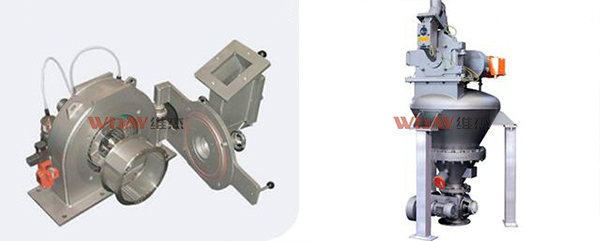

pulverizer It is composed of coarse crushing, fine crushing, wind conveying and other devices, and achieves the purpose of crushing in the form of high-speed impact. It is mainly used in medium fineness crushing operations in various industries, and its role is to process granular materials to medium fineness powders with required diameters for subsequent treatment or as finished products.

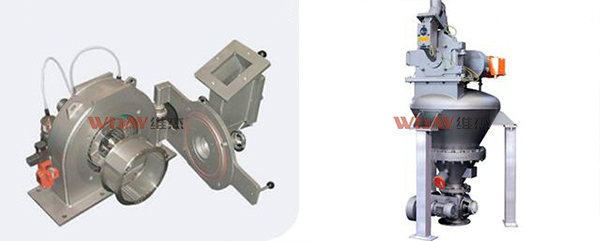

Explosion-proof pulverizer It is specially set for flammable and explosive materials, the main power adopts a new explosion-proof motor, the electrical system is also all explosion-proof design, the machine can be used in a high dust environment, for the safety of equipment and personnel provides a very good protection. The explosion-proof crusher uses the relative motion between the movable tooth plate and the fixed tooth plate, so that the material is crushed by the tooth impact, friction and the impact between the materials.

Mixing machine It is a mechanical equipment that uses mechanical force and gravity to evenly mix two or more kinds of materials. In the process of mixing, the contact surface area of the material can also be increased to promote chemical reactions; It can also accelerate physical change.

Horizontal mixer The working principle of the horizontal cylinder body is equipped with a double-axis rotating reverse pulp blade, pulp blade at a certain Angle to turn the material along the axial and radial circulation, so that the material quickly mixed evenly.

Vertical mixer. It can be widely used in various simple drying mixing and more complex vacuum drying processes in industrial production. The triple mixing function of the machine enables the user to obtain a better mixing effect in a very short time. Vertical mixers are widely used in adhesives, chemical products, coatings, cosmetics, food, pharmaceuticals, and plastics industries.

High shear mixer The machine generates high shear force and strong flow force in the mixer, and organically combines mechanical and gas nest shear to actively break up the pigment clots. This high-shear mixer reduces the number of pigment dispersion processes, reducing costs and speeding up production. Very suitable for printing ink, paint, industrial coatings, electronic ink and cosmetics and other materials.

pulverizer It is composed of coarse crushing, fine crushing, wind conveying and other devices, and achieves the purpose of crushing in the form of high-speed impact. It is mainly used in medium fineness crushing operations in various industries, and its role is to process granular materials to medium fineness powders with required diameters for subsequent treatment or as finished products.

pulverizer It is composed of coarse crushing, fine crushing, wind conveying and other devices, and achieves the purpose of crushing in the form of high-speed impact. It is mainly used in medium fineness crushing operations in various industries, and its role is to process granular materials to medium fineness powders with required diameters for subsequent treatment or as finished products. Mixing machine It is a mechanical equipment that uses mechanical force and gravity to evenly mix two or more kinds of materials. In the process of mixing, the contact surface area of the material can also be increased to promote chemical reactions; It can also accelerate physical change.

Mixing machine It is a mechanical equipment that uses mechanical force and gravity to evenly mix two or more kinds of materials. In the process of mixing, the contact surface area of the material can also be increased to promote chemical reactions; It can also accelerate physical change.