Composite New Materials

Superconducting material

Energy materials

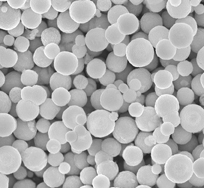

Nanomaterials

High end metal materials

Other new materials

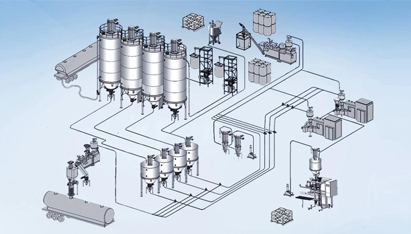

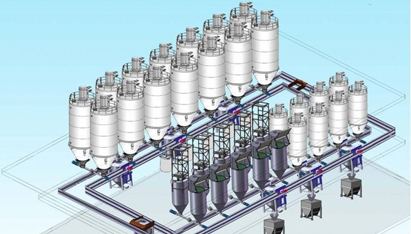

Pneumatic conveying system · Negative pressure pneumatic conveying · Dilute phase pneumatic conveying · Powder pneumatic conveying · Fluid conveying system · Dense phase pneumatic conveying system · Airflow conveying system

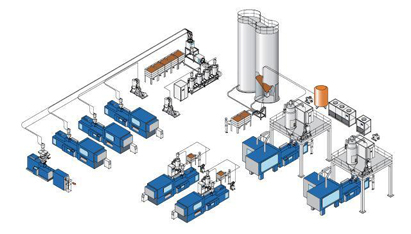

Automatic batching systemAutomatic batching system · Liquid material automatic batching system · Central feeding system · Automatic feeding system

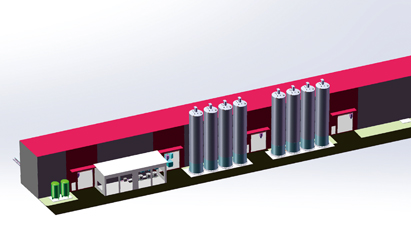

New material production lineOptical material production line · Fully automated production line for new materials

Supporting equipmentDouble planet mixer · Vacuum feeding machine · Spiral belt mixer · Plow blade mixer · Kettle dryer · Ton bag packaging machine