As a professional material handling automation comprehensive service provider, we provide customers with a complete set of pneumatic conveying production equipment and solutions according to their specific requirements. By using different pneumatic conveying design schemes, we can meet the different process requirements of customers.

System advantages20% improvement in production efficiency:High degree of automation, time-saving, labor-saving, and high production efficiency Reduce labor costs by 20%:Each production line only requires 1-2 people on duty, reducing labor and labor costs Environmental protection and health:Adopting automatic feeding, high-precision dust removal device and sealed pipeline transportation method, ensuring that the feeding is dust-free and the workshop is clean No blockage, easy maintenance:Stable operation, no blockage, simple structure, easy maintenance High precision measurement:The measurement and ingredient accuracy reaches 2 ‰, improving product quality and reducing the rate of defective products Simple and convenient operation:High degree of automation, simple and convenient operation

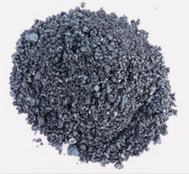

Lithium iron phosphate

Lithium cobalt oxide

Ternary material

Lithium manganate

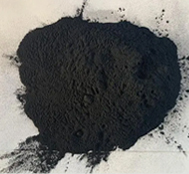

Natural graphite

Artificial graphite

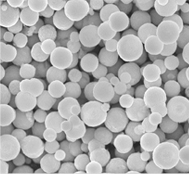

Plastic particles

Engineering plastics

Degradable plastic

Rubber

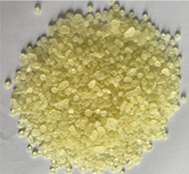

Resin powder particles

Nylon material

Chemical raw materials

Powder coating

Liquid raw materials

Pasty material

Powdery material

Auxiliary materials and additives

Composite New Materials

Superconducting material

Energy materials

Nanomaterials

High end metal materials

Other new materials

Flour

Powder

Fine granulated sugar

Particles

Glucose syrup

Tablets