From flour to dough

How does flour become dough?

starter

Yeast is a crucial component. It's like the soul of bread, like a baby that needs loving care. If the yeast is served well, then the bread is equivalent to the majority of success, because it directly affects the appearance level, taste and aroma of the bread. There are many types of yeast, but only a few can be used for bread making, and their forms are generally divided into two types: dry yeast and liquid yeast. Liquid yeast is fresh yeast, and its fresh activity is stronger.

The liquid yeast silently drives the whole wonderful fermentation process. It is with the help of liquid medium to complete the fermentation of dough, that is, the yeast is first placed in the liquid medium, propagated in the liquid for several hours, made of fermentation liquid, and then mixed with flour into dough. Commonly known as“One-step process”。

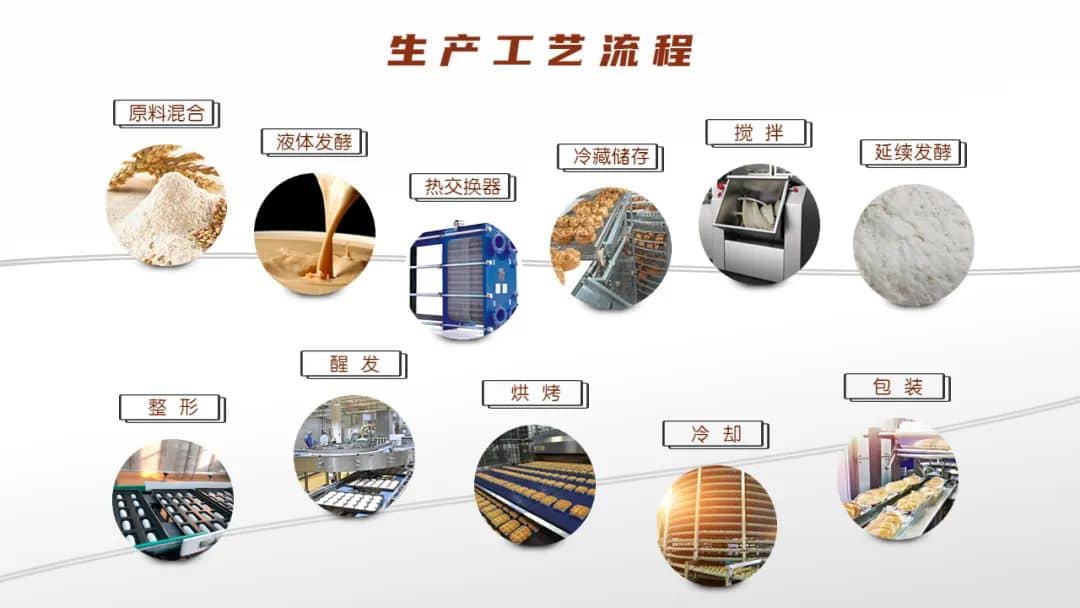

Process flow:

Raw material mixing→Liquid fermentation→Heat exchanger→Cold storage→stir→Continuous fermentation→plastic→awakening→bake→cooling→package

Compared with conventional yeast, the liquid fermentation method has higher requirements on the temperature, humidity and cleanliness of its production environment during transportation, storage and production. Wijay technical team designed a new pipeline transportation mode according to the characteristics of liquid yeast, so that liquid yeast can be transported in a closed and clean pipeline to reduce external environmental interference, and automated pipeline transportation mode can also better control the precise ratio of liquid yeast and flour, so that its mixing is more scientific and efficient, from raw materials processing to finished product packaging can realize all automatic and continuous production; The storage life of bread was improved and the aging speed was delayed. The fermentation time is shortened and the production efficiency is improved.

In the grain processing industry, pneumatic conveying system is an important material conveying method, which is widely used in the process of grain storage, cleaning, drying, grinding and so on. Compared with traditional mechanical conveying methods, pneumatic conveying systems have the following advantages

Pneumatic conveying system plays a key role in cement production, which is mainly used in raw material conveying, pulverized coal conveying, clinker conveying and other links in cement production line. The following is the application of pneumatic conveying system in cement production

The Central feeding system is a modern feeding solution that provides efficient and accurate material supply for a variety of industrial and commercial sectors. The system is composed of centralized control unit, conveying equipment and distribution mechanism, which can realize automatic and intelligent material supply management. The advantages and applications of the central feeding system are described below.

As a modern material supply solution, the central feeding system not only offers advantages in terms of increased efficiency and accuracy, but also makes a positive contribution to the environment and sustainable development. The important role of central feeding systems in environmental protection and sustainable development is described below.

Founded in 1926, Garton is one of the largest and most advanced food enterprises in Hong Kong at that time. Garton's main production facilities are located in Hong Kong and mainland China, producing food products including bread, biscuits, cakes, confectionery, etc. Since the 1980s, Garton has been actively developing the Chinese market.