First, the central console features:

1. Use PLC and large size 10.4 inch color human-machine interface touch panel, easy to understand operation;

2. Color written display of various Settings and operating states;

3. With material pipe vacuum-cleaning, automatic dust cleaning and dust collection central feed host A.B alternating automatic switching, manual material selection and error prevention functions;

4. Add raw material control chart to monitor the raw materials used by each forming machine. Suction. Missing materials and various abnormal phenomena of central main engine (motor).

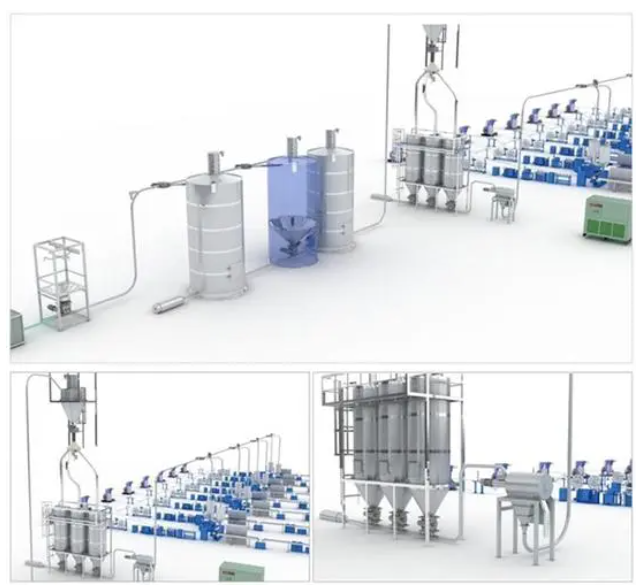

Second, central feeding system host features:

1. The motor does not stop the design, so as not to start the motor frequently, resulting in loss;

2. With safety pressure relief valve, when the movement pressure of the host is too large, the safety setting value is overloaded, and the pressure relief valve fully automatic pressure relief protection motor;

3. Two A.B alternate feed hosts, and designed an automatic switching valve to ensure the stability of raw material transportation.

Three, the characteristics of the automatic reversal of the cyclone dust collector:

1. Integrated design of air filter and cyclone dust collector to collect dust efficiently by natural centrifugal force;

2. Can attach high pressure gas storage tank, automatic cleaning filter;

3. The dust collector is equipped with a cut-off valve, which can effectively dust the dust without stopping the machine.

4. Rapid feeding station (diverging station) Features:

The diverging station is composed of multiple branches, and the raw materials of the same diverging pipe can be used for the injection molding machine, and each branch can quickly press the head to maintain air tightness; Can improve the efficiency of the system, refueling is convenient and fast.

In the grain processing industry, pneumatic conveying system is an important material conveying method, which is widely used in the process of grain storage, cleaning, drying, grinding and so on. Compared with traditional mechanical conveying methods, pneumatic conveying systems have the following advantages

Pneumatic conveying system plays a key role in cement production, which is mainly used in raw material conveying, pulverized coal conveying, clinker conveying and other links in cement production line. The following is the application of pneumatic conveying system in cement production

The Central feeding system is a modern feeding solution that provides efficient and accurate material supply for a variety of industrial and commercial sectors. The system is composed of centralized control unit, conveying equipment and distribution mechanism, which can realize automatic and intelligent material supply management. The advantages and applications of the central feeding system are described below.

As a modern material supply solution, the central feeding system not only offers advantages in terms of increased efficiency and accuracy, but also makes a positive contribution to the environment and sustainable development. The important role of central feeding systems in environmental protection and sustainable development is described below.

Founded in 1926, Garton is one of the largest and most advanced food enterprises in Hong Kong at that time. Garton's main production facilities are located in Hong Kong and mainland China, producing food products including bread, biscuits, cakes, confectionery, etc. Since the 1980s, Garton has been actively developing the Chinese market.