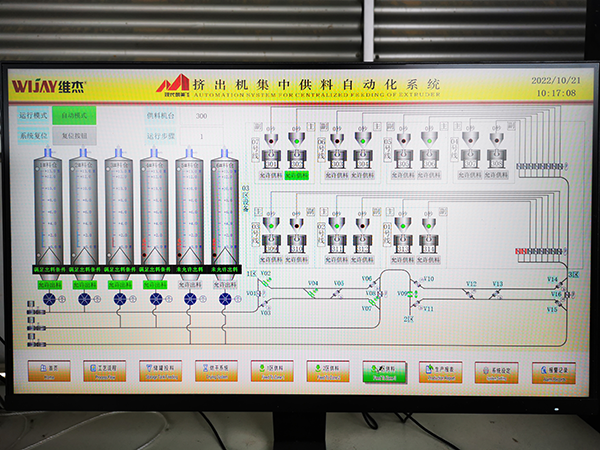

The innovative material automation system designed by Wijie continuously supplies 6 different materials to 46 large sheet extruders of customers, the feeding speed reaches 36T per hour, the conveying distance exceeds 200 meters, the material storage capacity reaches 1200 tons, and realizes the real-time monitoring and control of the material temperature and temperature, which is the traditional way of combining multiple small dryers and suction units. Functions that cannot be implemented.

Our innovative fully automated batching valve set enables arbitrary connection of 6 large storage bins, 6 drying systems and 46 material points, making it easy for customers to achieve flexible production.

The project central control information system can help customers analyze and understand the real-time storage capacity of materials and the material consumption data of each production line. Customer managers can set up office computers and mobile terminals to know the system movement and key data at any time.

In the super large centralized feeding system, the positive pressure interphase transport technology and air flow control technology have unparalleled advantages, high information and flexibility make our customers achieve reliable quality assurance and production cost reduction in the production process!

Wijay uses innovation to achieve customers, engineering to create the world!

In the grain processing industry, pneumatic conveying system is an important material conveying method, which is widely used in the process of grain storage, cleaning, drying, grinding and so on. Compared with traditional mechanical conveying methods, pneumatic conveying systems have the following advantages

Pneumatic conveying system plays a key role in cement production, which is mainly used in raw material conveying, pulverized coal conveying, clinker conveying and other links in cement production line. The following is the application of pneumatic conveying system in cement production

The Central feeding system is a modern feeding solution that provides efficient and accurate material supply for a variety of industrial and commercial sectors. The system is composed of centralized control unit, conveying equipment and distribution mechanism, which can realize automatic and intelligent material supply management. The advantages and applications of the central feeding system are described below.

As a modern material supply solution, the central feeding system not only offers advantages in terms of increased efficiency and accuracy, but also makes a positive contribution to the environment and sustainable development. The important role of central feeding systems in environmental protection and sustainable development is described below.

Founded in 1926, Garton is one of the largest and most advanced food enterprises in Hong Kong at that time. Garton's main production facilities are located in Hong Kong and mainland China, producing food products including bread, biscuits, cakes, confectionery, etc. Since the 1980s, Garton has been actively developing the Chinese market.