Introduction to special Material handling (inert gas) systems

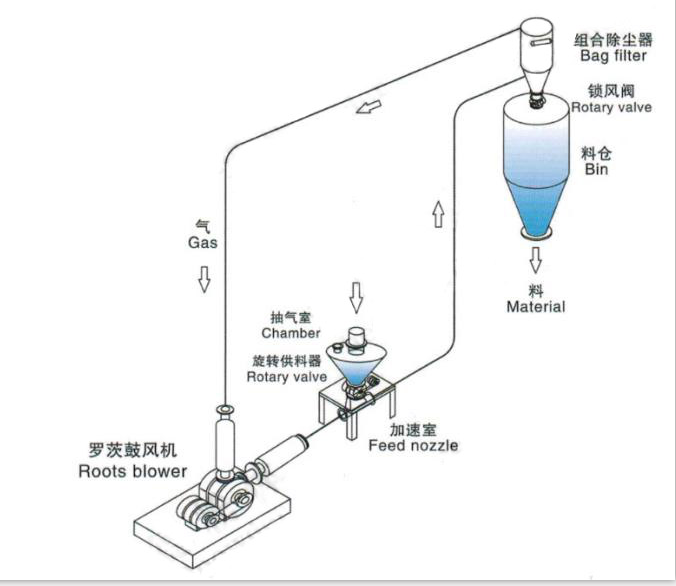

Generally, Roots blower is used as the air source, and rotary blanking valve is used as the feeding device. Materials fall into the conveying pipeline through the rotary blanking valve, and are mixed with high speed air before being transported to the target receiving bin. The inert gas filtered through the dust removal and pressure relief device is re-connected to the entrance of Roots blower. Suitable for chemical instability, flammable, explosive material conveying project (lithium electric positive and negative electrode material conveying).

Special material handling (inert gas) system advantages

Low pressure, reliable transmission, effectively prevent the material deterioration and explosion problems that may occur in high-speed transportation.