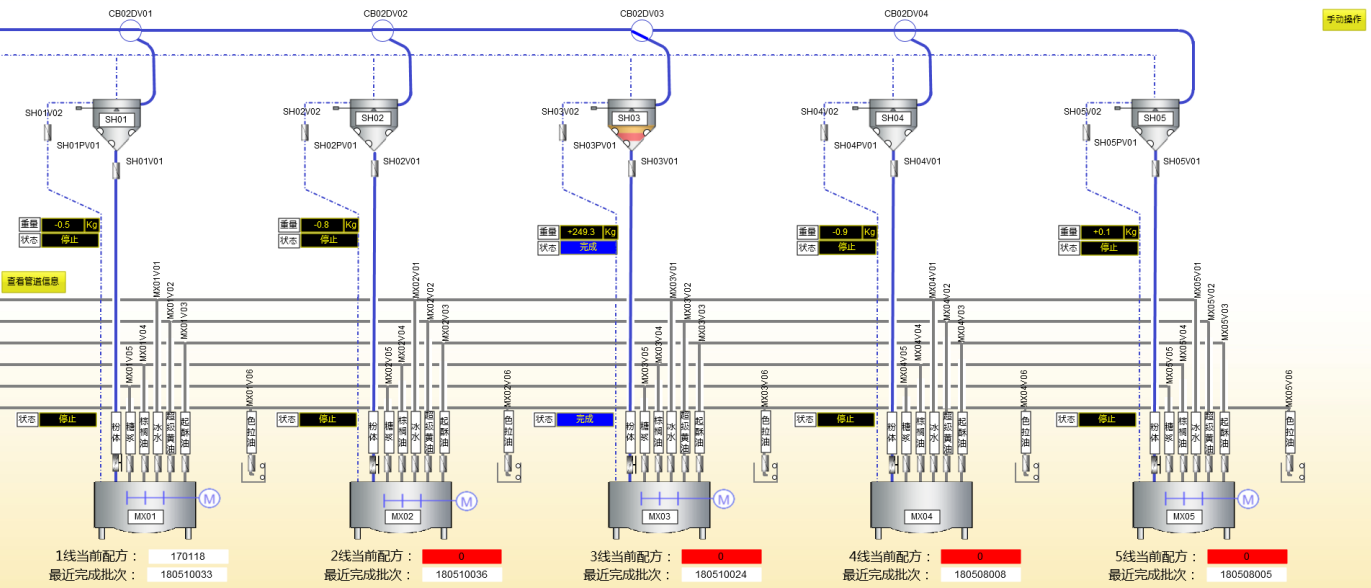

This system is for different formulations automatic ratio, only the different formulations into the system can be automatic measurement ratio, to provide a strong guarantee for production automation, greatly improve the previous manual weighing ratio of low efficiency problems and product department stability problems. Different formulations are recorded and stored to facilitate data tracing.

Automatic batching system and Ethernet, ERP system can be seamlessly compatible, truly achieve remote production control, reduce labor costs and greatly improve the factory production, automatic batching precision, good stability performance greatly improve product stability. Automatic batching is carried out in a closed environment, increasing the cleanliness of materials and improving the cleanliness of the production workshop. It is a necessary system for modern production enterprises.

Automatic dosing system is also called automatic feeding system,It is a system equipment that replaces manual feeding with a series of automatic batching equipment, which solves the problems of inaccurate manual feeding, easy to make mistakes, high labor cost, increases the stability of feeding, and easy to ensure product quality. The feeding of some chemicals has a certain potential harm to the operator, and the use of automatic dosing is also the trend.

1, the formula is stable, high efficiency, with data storage traceability function, to improve the production of information basis. Can connect with ERP and other management software to achieve management remote control. Improve management efficiency.

2, the measurement accuracy is high, the accuracy can be as high as 0.1-0.5%, which can avoid unnecessary material waste;

3, the whole process of automatic control, no need for manual intervention, automatic action, greatly improve production efficiency;

4, for the enterprise to save a lot of labor costs, for the enterprise to bring great benefits.

5, can achieve a variety of materials mixing and matching ingredients, single material measurement ingredients, multi-material mixing ingredients and other characteristics, coupled with high-precision weighing system, so that the production of ingredients process more intelligent, automated. Save time, save cost, and bring greater benefits.

6, powerful. Using advanced monitoring system, it can realize complex formula management, order management, history management, system control optimization, automatic start and stop management, chain management, remote diagnosis, detection and control.

Automatic batching system application industries and applicable materials

Application field:It is widely used in food, new energy, plastics, mining, chemical, pharmaceutical, glass, steel, rubber, coal, feed and other industries

Applicable materials:Powder, granular, block, flake and liquid materials;